About Us

- Home /

- About Us

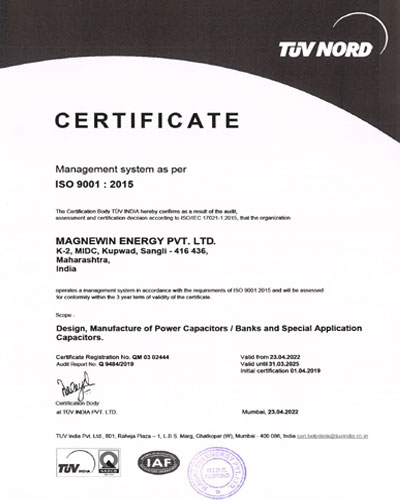

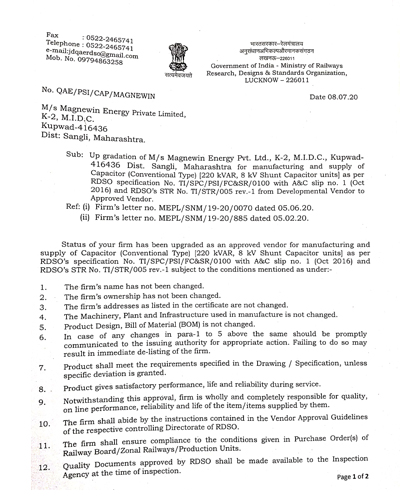

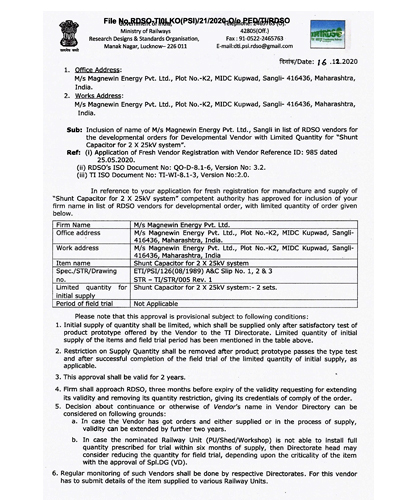

Magnewin Energy Private Limited is an ISO 9001:2015 Certified and a Custom-built Capacitor manufacturing Company professionally organized. It is managed with long standing experience, profoundly interested in Enhancing Power and possesses an exceptional track record since its inception.

It was started with a humble beginning in the year 1994 at Sangli (Maharashtra) and reached the status of a leading manufacturer of capacitors for variety of applications in power system utilities, industries and research activities.

Over the years 'Magnewin' has developed its own capacitor manufacturing processes using high quality imported raw materials. Tests are carried out rigorously abiding by the National & International Standards. The products have been regularly exported to more than 20 countries.

It retains its position as one of the leading manufacturers of shunt capacitors for power frequency applications in - LV / MV/ HV systems both fixed and automatic switched type and shunt passive tuned/ detuned filters.

"Magnewin" also has been catering to the needs of specially designed water cooled capacitors for industries such as induction heating, melting and hardening applications; custom - built for energy storage, pulse discharge, medical equipment, impulse generators & voltage dividers and so on.

'Magnewin' is a unique enterprise that can address the critical needs of industries and utilities having sophisticated controllers and facing power quality related problems. We have been developing capacitors to meet the stringent requirements under adverse conditions of operation and offering solutions for energy conservation.

'Magnewin' is a unique enterprise that can address the critical needs of industries and utilities having sophisticated controllers and facing power quality related problems; have been developing capacitors to meet the stringent requirements under adverse conditions of operation and offering solutions for energy conservation.

Electricity has now been considered as the life line in the rapid growth of any developing country and India is no exception to it considering its march towards becoming a super power in years to come. In current scenario the bridge between generation and demand is widening every day, even though all attempts are made to minimize it. Under the given situation it becomes imperative to use the available power at its highest efficiency and use of capacitors takes the first & foremost step in energy conservation.

"Magnewin" is committed to develop highly reliable capacitors, be it required for electrical utilities / for industry / for defense or for R & D institutions. "Magnewin" is committed & proud to develop environmental friendly world class technologies / materials and products that save valuable Foreign exchange and make our country self- reliantin its path of progress to become super power. We at " Magnewin " are proud to be shareholders in the National Energy Conservation programme of India. Magnewin will be known globally as one of the most respected capacitor manufacturing company by 2021.

Mr. Vijay Chippalkatti

( Director )

Our Quality Policy

We, the management, staff, and employees of "Magnewin Energy Private Limited" ensure that we meet our responsibilities and obligations to our customers, our people, our partners, and our suppliers; we are committed to the following quality objectives:

• Deliver on-time & on-quality products and services that meet or exceed our

customer's expectations.

• Identify and understand our customer's expectations and implement improvements

to increase customer satisfaction.

• Enable and engage our people at all levels in a relentless drive to improve

operational performance along the value chain from suppliers to customers.

• Increase the motivation and skills of our people to add value to our customers and

our businesses, through continual training and development.

• Leverage our partners & suppliers' strengths to improve our products and our

business from product design through production, installation, and operation.

• Embed social responsibility & company ethics policies in our business practices.

• Continually improve environmental, health and safety performance through all

products, operations, systems, and services..

To see beyond the horizon, challenging ourselves for continued betterment, to move forward with competitive spirit abd strive to develop the most preferred products in-house with our own standards

To be the most preferred electrical manufacturer nationally and globally under the brand name of Magnewin

Company adopts internationally followed latest technology, sells products at competitive prices, attempts to deliver as per the agreed upon schedules and promptly cariies out after sales service & attends to the maintenance problems, if any; keeps in touch with customers & obtains feedback continously for corrective actions so as to improve the quality & reliability.

- 1994 - Company Establishment 1994 - Low Voltage film foil capacitors up to 1000 volts.

- 1995 - Medium Voltage Shunt Capacitors up to 11 kV Network.

- 1996 - High Voltage Shunt Capacitors up to 33 kV Network.

- 1998 - High Voltage Shunt Capacitors up to 145 kV Network.

- 2000 - Special application Capacitors.

- 2003 - Energy Storage Capacitors

- 2004 - Medium & High frequency Water Cooled Capacitors

- 2007 - Low Inductance Energy Storage Capacitors

- 2009 - 800 KVp Voltage Divider

- 2010 -20 KJ Single case Energy Storage Capacitors

- 2011 - 7200 kvar, 3 kv water Cooled Capacitors.

- 2012 - Commissioning of state-of-the-art manufacturing and testing Facility.

- 2012 - Low inducatance insulated case Energy Storage Capacitors

- 2013 - 100 kv Energy Storage Capacitors

Training is considered as the most important tool to develop the skills of our both commercial as well as technical staff. Regular Training is imparted by seniors from the company as well as invited guests who are experts in Power capacitor manufacturing.

Plant has a total shop floor area of 22600 sq. feet including world class dust free room of area 3100 sq. feet for manufacturing all the types of capacitors. Separate store ( clean air conditioned ) is used for Class "A" raw materials like film, foil and insulating materials. Another store for rest of the materials is maintained. All the materials are carefully handled using latest material handling equipment. The plant consists of necessary machinery for winding the elements, their testing and assembly for the capacitors. The plant also consists of the latest facilities for carrying out the routine and type tests as per national and international standards. The special application capacitors are also tested according to the prescribed specifications by the customer.

Imported bi-axially oriented double hazy (both side rough) polypropylene film and capacitor grade 99.9% pure aluminum foil are used as a dielectric and electrode. Wrinkle free elements are wound in a class 100 environment on semi-Automatic winding machines with edge and end folding of aluminum foil. Each wound dry element is subjected to DC over voltage test to eliminate faulty elements. Numbers of elements are stacked together to form a dry pack.

They are interconnected in series/parallel combinations to achieve the desired capacitance, voltage and kVAr ratings for the capacitor. Internal discharge resisters are provided across each capacitor to reduce the voltage below 75 volts within prescribed time as prescribed in the standards. The dry pack is wrapped with optimal number layers of high quality insulating paper before inserting into a pre-treated sheet metal container. Leak proof porcelain bushings of appropriate BIL are TIG welded on the embossed top lid, which is TIG welded to the container-Automatic welding machine.

The capacitors are then processed in PLC controlled autoclave for drying and vacuum treatment.The heating, drying and vacuum levels are monitored by using precision online instruments for preserving the quality of capacitors. They are then impregnated under vacuum with purified and degassed NPCB capacitor fluid.

Fabrication

The Fabrication Division has full - fledged in house fabrication shop incorporates hydraulic power press break up to 150 tons, power shear, die tools, punches and semi-Automatic welding machines etc.

These in house facilities ensure to get the fabricated containers and cubicles, capacitor mounting frames and elevating structures on time with quality workmanship.

Testing

All capacitors are subjected to routine tests as per relevant IS/IEC standards and are also subjected to over voltage to ensure voltage withstand capability as per the company policy.

Randomly picked up capacitors are subjected to Type test as per the relevant standards .

Further, at regular intervals capacitors are tested at independent NABL accredited laboratories to ensure the quality and reliability.

Uality Control

Quality Control is an essential feature and all the incoming materials are inspected as per the relevant standard and specifications.

In-process inspections are regularly conducted at each process level. All the records are documented and maintained in accordance with ISO 9001.

Pre-despatch Inspection

Each capacitor unit / bank /panel undergoes pre dispatch inspection by the quality control department.

Equipment's are packed carefully so that they are received by the customers securely and safely without any transit damage.

Life Expectancy

Life Expectancy is another important aspect for which the company has been paying much attention.

But for the state of art plant and machinery, use of world class raw materials, updated manufacturing processes with strict quality control through precision online monitoring instruments, proper material handling systems and rigorous testing under extreme conditions - Magnewin capacitors can be assured for minimum 20 years of trouble free service life under normal working conditions.

R&D is continuous ongoing activity being carried out to improve the quality, enhance reliability and increase the service life of capacitors.

Quality improvement techniques are in progress by further improving the manufacturing processes, through accurate automation and installing additional precision online instruments for monitoring the quality of capacitors at every stage.

The tasks are to formulate new rigorous in-house test standard to assess life expectancy and behavior of capacitor under adverse operating and environmental conditions.

Developing new dielectrics with high energy density for compact size and capacitors for special applications are the primary objectives of R&D department.

At present 'Magnewin' is proud to be the only company in India to manufacturer such a wide range of capacitors, which could be possible on account of its innovative thinking, strong expertise knowledge coupled with practical skills, passion for research and development through innovative thinking.

R&D is an essential prerequisite in the highly competitive world for successful running of a manufacturing industry like ours due to the fast changing technologies & to keep abreast of the developments.

- Raw material used are of world class quality, sourced from best manufacturers in world.

- Elements are wound in totally dust free ( 100 PPM class ) winding room on a Automatic Winding Machine.

- Extended Foil design is used to minimize inductance and contact resistance, resulting in very low losses.

- Elements are externally connected in series / parallel combination by a unique process of soldering.

- Very Low values of equivalent series inductance ( ESL ) and resistance ( ESR ) Capactiors most suitable for :

a) Frequent Switching Operations

b) Large inrush current and out flow current handling capacities. - World class sophisticated ( impregnation ) vacuum chambers are used for Impregnation of Capacitors with Non-Toxic, Non-PCB Oil under a very high degree of Vacuum.

- Every Capacitor unit manufactured undergoes testing as per relevant applicable standard.

- Randomly selected Capacitors are subjected to Type Test. Magnewin does have in house testing equipments like Impulse test Generator for Impulse Test, Schering Bridge for measurement of tan delta ( losses ), Inductance measuring equipments. We also get the capacitors tested periodically from the Independent NABL accredited test labs in order to ensure Quality.